AS 200 jet pro / pharma — RETSCH Air Jet Sieving Machine from Official Representative Makrolab LTD Ukraine

For sieving specialists: With the AS 200 jet pro and the GMP-conform AS 200 jet pharma, laboratory teams get a space-saving and user-friendly all-in-one sieving machine.

Sieve, weigh, and evaluate with a single device: Combining state-of-the-art air jet sieving with a built-in balance ensures precise and reliable sieve analysis in the shortest amount of time. The integrated AS 200 jet pro software via touch display ensures smart processes with maximum ease of use.At a glance: Versatility and autonomy in a tabletop device format

- User and audit trail management (optional in the pharma version)

- Easy access to all operating parameters

- Space saving device with a small footprint (460 x 288 x 305 mm)

- Integrated balance

- Onboard computer

- LAN and USB interface

- Touch display: intuitive system control and result evaluation

- Clear 10-inch user interface

All you need to use the AS 200 jet pro / pharma is an external industrial vacuum cleaner. You can find suitable vacuum cleaners here:

Really robust and super sensitive: the integrated balance

The balance, which has been integrated into the machine design for the first time, is extremely robust – and patented in this setting! You can even use a rubber hammer to loosen any material that sticks to the lid during sieving without affecting the accuracy of the balance.

The integration of the balance not only saves additional space in your laboratory but also reduces errors. There is no need to transfer material between the sieving machine and an external balance, which effectively prevents material loss. Thanks to a high weighing readability of 0.01 g, all necessary data are recorded precisely during sieving, and the respective particle size is evaluated using the integrated software.

Modern air jet sieving technology that protects your sample

The air jet sieving process:

✔ eliminates the need for additional mechanical sieving aids

✔ protects the sample material through individual selection of pressure, speed and height of the used sieve

✔ enables short sieving times (typically 2-3 minutes per process)

Comply with quality assurance standards such as ISO 9000 ff

As part of test equipment monitoring, you can calibrate the sieving machine (clock, speed & pressure sensor) and internal balance. As part of the RETSCH maintenance service, we are happy to take care of all calibration processes for you.

Native software integration – your digital assistant in the laboratory

Thanks to native software integration, you always have control over the entire process chain via an intuitive touch display:

✔ Sieve Management

✔ Parameter Setup

✔ Method Setup

✔ Sieve Analysis

✔ Weighing

✔ Data Evaluation & Reporting via USB or LAN connection

✔ Optional User Management (in the pharma version)

Our patent, your advantage: combined sieving and weighing

The patented combination of sieving and weighing in the AS 200 jet pro offers you real added value.

The principle behind this: for sieving, the sieving chamber is connected airtight to the vacuum cleaner. For a precise weighing process, the airtight sieving chamber is mechanically decoupled.

Your advantage in everyday laboratory work: error-free, time-saving weighing and subsequent evaluation in a single process, without the hassle of transferring the sieve between the machine and the balance.

Various test sieves for your requirements – the choice is yours

Not only existing customers benefit from our modular and sustainable development design. The AS 200 jet pro allows the use of all RETSCH test sieves with a diameter of 203 mm (8") and 200 mm (with adapter) and a height of 25 and 50 mm (1" and 2").

Step by step to the desired result

With the integrated software, you can easily perform both simple routine sieving and complex distribution analyses: and display all results immediately afterwards in both graphical and tabular form.

RETSCH's Guided Sieving and Weighing Assistant ensures accurate results.

The internal wizard guides the user step by step through the entire process. Every process step is clearly explained and ensures reliable sieve processes. Human errors are reduced to a minimum.

The optional “Weighing Assistant” recommends a suitable sample amount which avoids errors based on overcharging the sieve but still keeping a minimum amount for a reliable sieve analysis by considering the sample’s representativeness.

The “Weighing Assistant” exclusively can be used with RETSCH test sieves and can easily be activated/deactivated in the method.

Exclusive features of the AS 200 jet pharma model

The AS 200 Jet Pharma is a separate model adapted to the needs of the pharmaceutical industry and other regulated environments. It offers all the functions of the AS 200 Jet Pro and has several additional features.

Your partner for Good Manufacturing Practice (GMP)

The AS 200 jet pharma variant offers you all the functions you need to meet the requirements of modern particle size analysis in accordance with GMP guidelines.

The system meets the software validation requirements according to

✔ ISPE GAMP 5

✔ FDA 21 CFR Part 11

✔ EC GMP Annex 11

for fulfilling with the highest standards in quality assurance.

The user management ensures complete transparency and security through the optional assignment of hierarchical access rights and passwords, as well as the setup of legally compliant e-signatures.

Additional features

Accessories and Additional Features

With the optional high-performance cyclone, even extremely fine particles can be recovered without significant pressure loss during the sieving process. In addition, the use of a cyclone helps to extend the service life of the vacuum cleaner filter.

Use your existing external balance

Optionally, you can easily connect your existing, qualified balance as an external device via USB. The internal software already offers factory-installed connection options for the most common balances.

Advanced data transfer via LIMS

Data can be transferred from the AS 200 jet pro / pharma to your Laboratory Information Management System (LIMS) via a network connection.

Learn everything you need to know about modern air jet sieving

Air jet sieving is the optimal method for dry sieving of samples with a high proportion of fine particles. Compared to traditional sieving methods, this process saves time and reduces your costs in the long term.

✔ As an alternative to vibration screening, this method offers a significantly higher process speed for fine particle sizes.

✔ Unlike other methods, air jet sieving uses only one sieve per sieving process.

The rule of thumb for choosing the best parameters:

- Sensitive samples should be sieved with low vacuum pressure to protect the material. The vacuum pressure can be adjusted variably via the touch display. In addition, the sieve height can be varied to adjust the impact effect.

- Higher vacuum pressure and/or a low test sieve are suitable for agglomerated samples. The increased impact intensity allows even strong agglomerates to be broken up in a short time.

Guided Sieving: After selecting the desired sieving method, the software guides you step by step through the sieving process. You can precisely control all relevant parameters via the control panel of the AS 200 jet pro. In addition, Guided sieving improves safety, as each step is clearly described, thereby reducing human error.

- The speed of the nozzle influences the frequency of impact of the sample during the sieving process.

- The vacuum has a significant influence on the sieving process and can be controlled by automatic vacuum cleaner control.

- The sieving time can be set to the nearest second.

Comprehensive display of results:

The following evaluation data is available as standard. A complete list, functions, and the underlying formulas can be found in our knowledge base:

- Various percentiles

- quantiles

- Uneven grain size

- Span value

- RRSB

- AFS fineness number

- Specific surface area

In addition, further comparisons, limit value monitoring, and trend analyses can be generated.

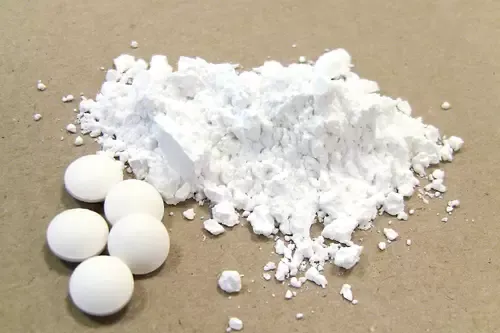

Typical Sample Materials

RETSCH's Air Jet Sieving Machines AS 200 jet pro / pharma are ideally suited for separation, fractioning and particle size determination of cement, pharmaceutical materials, ceramics, chemical products, cosmetics, food, minerals, pigments, plastics, powder coating, rubber, toner particles and washing powder.

Functional Principle

The AS 200 jet pro / pharma is equipped with a rotating slot nozzle, over which the sieve and cover are placed. A vacuum generates a strong air jet that swirls the sample particles on the sieve and distributes them. Sample material that is smaller than the mesh size of the sieve is transported by the reverse air flow to the cyclone or vacuum cleaner. The air jet also ensures continuous resolution of agglomerated particles (deagglomeration) and cleaning of the sieve mesh.